used caterpillar hardness tester to test knife blade|Measuring the hardness of steel and the sharpness of knives : services The Rockwell hardness test is the most widely used method for testing knife blade hardness. It involves applying a fixed load to the blade and measuring the depth of . web31 de mai. de 2023 · Opiniones de la tragaperra Boogie Monsters ¡Casinos online para jugar a Boogie Monsters gratis! Bonos de Microgaming enero 2024 Política de cookies Este sitio web o sus herramientas de terceros utilizan cookies, que son necesarias para su funcionamiento y necesarias para lograr los fines ilustrados en la política de cookies.

{plog:ftitle_list}

WEB19 de fev. de 2015 · SMOOTH - Correria - Part. Ber (Cartel Mcs) & Luccas Carlos - Prod. D.Sydens (Official VideoClip) - YouTube. 0:00 / 5:02. SMOOTH - Correria - Part. Ber .

There is a listing in local classified near me for 2 hardness testers. Not much information, just these pics. What do you think? If I go to have a look how. I have found rockwell testers to be useless for testing blade profiles. I have to make flat sections to test under the hardness tester . blade profiles test low as the diamond . The Rockwell hardness test is the most widely used method for testing knife blade hardness. It involves applying a fixed load to the blade and measuring the depth of . I have used this hardness tester for over twenty years with great results. It is a PTC 415C hardness tester. It is portable and chucks up into a drill press. It is very precise .

The Rockwell Hardness Scale is a technique to measure the hardness of the steel used to make knives. There are different Rockwell scales because steel is used for many uses. In the knife-making industry, the . When I was making knives I never tested for RC hardness, but there are other ways to get a feel for edge hardness/heat treat quality. The "brass rod" test (google it) is a .

Hardness Tester Used To Measure Metals and Alloys. Here’s a breakdown of the different Rockwell scales and which materials they’re applied on: Scale A – Cemented carbides, .

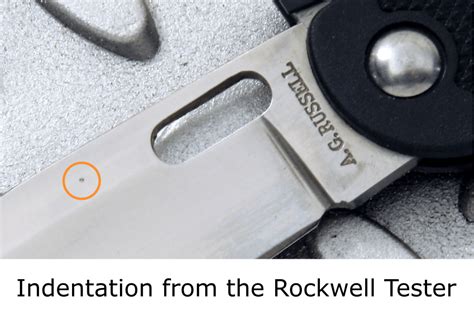

They have developed a machine called the CATRA sharpness tester which checks the sharpness of a blade by pushing it into a section of rubber which shows a real time . The usual way to test the hardness of steel is with a Brinnel or Rockwell test. Both tests are similar and work by testing the amount of displacement given a fixed force and . The tool we use to test hardness is called the Rockwell hardness tester. The Rockwell hardness tester applies an indentation force to the material being tested and . Popular knife brands like Spyderco, Cold Steel, CRKT, Kershaw, Buck, Boker, Benchmade, and Emerson tend to produce blades within this hardness range. Kitchen Knives and Japanese Blades: 61 to 63 HRC A C .

Several methods can be used to test knife blade hardness. These include the Rockwell hardness test, the file test, and the use of a hardness tester. . The file test is a simple yet effective method for testing knife blade hardness. It involves using a set of files with known hardness levels to scratch the blade. The file that can scratch the . Lately I am more and more interested in edge holding and cutting performance I have used a digital Rockwell tester that I have access to, to test the hardness of a number of knives that I own. :) Here are the results. .With the BESS everyone can test the sharpness of a knife. The Edge-On-Up test tools are relatively affordable. . For anyone who truly loves sharp knives the Edge-On-Up sharpness testers are simply must-haves. If you want to improve your sharpening skills or want to test your gear in a reliable way a good measuring device is indispensable. It . As a guide most good quality knife blades have an HRC rating of 55-66 (the higher the number the harder the steel is) – I.O.Shen knives for example have an HRC rating of 62. . I.O.Shen knives for example have an HRC rating of 62. The last type of hardness test is for ‘rebound hardness’ which measure the elasticity of the material when .

One test I talk about a lot in my previous articles is the paper test. For me, this is the easiest and best way to test the sharpness of your knife. All you will need for this test is your knife and a piece of paper. To do this test, try slicing the paper with your knife. If the knife catches the paper and slices it easily, you have a sharp blade.

Both tests are similar and work by testing the amount of displacement given a fixed force and testing spike. The Rockwell test (specifically the 'C' scale Rockwell test used for testing hardened steel) uses a diamond point, not unlike a record player's needle, and a fixed amount of force (150 kilogram if I recall correctly).Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below. The Rockwell Hardness test measures the depth of penetration of an indenter into a material. In the case of kitchen knives, a diamond cone or a hardened steel ball is used to apply a specific load to the blade. . dicing, and chopping softer ingredients. Medium-Hard Blades: Kitchen knives with medium hardness, ranging from 57-62 HRC, provide a .

Rotate your blade regularly to ensure consistent heating on all sides. Keep an eye on the blade’s color, which will change as it heats. You’re looking for a bright cherry red. Step 4: Test for Non-Magnetism. As your blade heats, periodically test it with a magnet. We recommend testing your knives’ sharpness on different materials, according to their original purpose. 1. The thumb test. The thumb test seems a little scary at first - and we urge caution! - but it is the fastest and most reliable knife sharpness test: Put the thumb lightly on the edge, and pull away across the blade (never along). If it . Basically, they are files hardened to different specific hardnesses and you see at what point they start cutting your blade/test piece. Most otjer testing wont necessarily give you a number, but it can still be useful. . A sword is used very differently than a kitchen knife. More hardness generally means more edge retention, but more brittle.Edge-On-Up Professional Edge Tester. Test the sharpness of your knife or tool edge. Backed by the Sharpening Supplies Guarantee. Free Shipping. . Yes, this is commonly called the BESS Tester. BESS is the measurement scale used by this knife edge tester. Need more information? Call a Product Specialist Monday through Friday, 8 a.m. - 4 p.m. CT

Here is another method of testing blades. It does not test the hardness of the blade but, rather if the temper of your blade is correct for that type of steel. This test is called the brass rod test, I learned it from reading Wayne Goddards . The BESS Universal certification provides the expected test results (sharpness ratings) for common types of blades when used with the Edge-On-Up tester: Double-edged razor blades measure between 50 and 80 .

A scratch test determines a mineral’s hardness by scratching it against a tool or another mineral of known hardness. A scratch test is based on the Mohs scale, which measures the relative hardness of minerals. Scratch .

A blade’s hardness is based on the Rockwell scale. The Rockwell scale was cocreated by Hugh and Stanley Rockwell in the early 20th century to test the hardness of different materials. There are several different scales by which a material’s hardness is measured on, but blade steels are measured on the C scale.

Using This Test For Knives. The hardness of a knife blade is an important factor in its performance. A blade, that is too soft, will not hold an edge, while a blade, that is too hard, may be brittle and prone to chipping or breaking. . However, advancements in hardness testing technology have led to the development of other hardness testing .

16pc Steak Knife and Bistecca Plate Set + 8" Chef's Knife + 3.5" Paring Knife Bundle 9.99 4 22% Savings (157) Aprons Aprons. Eco Modern Apron Benny's Eco Modern Apron Shop all Aprons > View product detail Eco Modern Apron (Ecru) (22) View product detail Eco Modern Apron (Slate) (22) . How to use Rockwell Hardness Files for knife making. Testing files can be used as an affordable way to test the hardness of knife blades after heat treating..

Knoop Test. The Knoop hardness test is the most common testing method used for very soft and thin materials, like gold. The indenter is similar to the pyramid-shaped version used in the Vickers test but is more elongated on one axis, giving it a rectangular shape. The Knoop test indenter shape helps it distribute its load over a larger area.

Portable Grain Moisture Meter tv shopping

As a knife maker, you may have used a hardness tester to perform hardness tests on your knives or saw blades. Ames portable hardness testers are a preferred model for blade makers to perform quick hardness tests. Many knife makers may not have the budget to purchase a new Ames Portable Hardness Tester. Used testers available on eBay and . Pool noodles can be found really cheap at shops like Dollar Tree, 99 Cents and other similar shops. Through experience, I’ve used pool noodle to test a whole range of blade sizes from mini pocket knives to full length longswords. In conclusion; I suggest anyone and everybody to give pool noodle blade sharpness testing a try.Additional Rocks. Shale: 2-3 (very soft, easily scratched) Limestone: 3 (scratched by copper penny) Marble: 3-4 (softer than granite, often used in sculpture) Slate: 3-5.5 (depending on composition) Granite: 6-7 (hard, durable, used in countertops) Basalt: 5-6.5 (volcanic rock) Hardness Variations in a Single Mineral. It is essential to note that hardness can vary within a . Looking at the accuracy of the hardness testers listed on that website, ptc1.com, their Rockwell hardness testing machines have an accuracy of +/- 1.5 points!!!! I don't have any experience working with hardness testers, or how accurate they SHOULD be, but plus or minus a point and a half seems WAY TOO much.

Try out and buy a used hardness tester?

The very good toughness of MagnaCut meant that it didn’t chip despite this relatively high hardness and the difficulty of the test. . I know that one does not normally make knife blades of titanium, but I gather that Ti is extremely corrosion resistant, used for saltwater applications, etc. . I would’ve liked to see edge retention .

Test Steel Hardness Of Knife Blades – Rockwell Scale

webCuphead é um jogo clássico de plataformas e tiros em 2D, intensamente focado nas batalhas contra chefões. Inspirado por desenhos dos anos 30, o visual e o áudio foram detalhadamente recriados com as mesmas .

used caterpillar hardness tester to test knife blade|Measuring the hardness of steel and the sharpness of knives